titanium tubes. fittings. flanges

titanium tubes. fittings. flanges

2023年12月20日星期三

The Importance of check valves in Power Plants

2023年12月4日星期一

Top-Quality Titanium Alloy Flanges & Titanium Forged Flange for Sale

Top-Quality Titanium Alloy Flanges & Titanium Forged Flange for Sale

When it comes to industrial projects, reliability and durability are crucial. That's why we offer a range of top-quality titanium alloy flanges and titanium forged flange options for sale. These components are engineered to meet the demands of various industries, ensuring optimal performance and longevity.

Our titanium alloy flanges are known for their strength and versatility, while our titanium forged flanges offer exceptional durability and reliability. With customization options available, we can tailor our products to meet your specific project requirements.

Whether you're in the aerospace, marine, or chemical industry, our titanium flanges provide an ideal solution for your needs.flange's design and highlight its strength and durability. Use lighting to accentuate the metallic shine of the titanium and convey a sense of quality and sophistication. Show the flange in use, connected to pipes or machinery, to showcase its functionality and practicality in industrial applications.

Key Takeaways

- Titanium alloy flanges and titanium forged flanges are reliable and durable components for various industrial applications.

- Customization options are available to tailor our products to your specific project requirements.

- Our titanium flanges are ideal for industries such as aerospace, marine, and chemical.

Titanium Alloy Flanges - Reliable and Durable Components

When it comes to industrial applications, reliability and durability are crucial attributes. Titanium alloy flanges are widely used in many industries as they offer superior performance in harsh environments.

Titanium alloy flanges are known for their high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. These attributes make them suitable for critical applications, including aerospace, chemical processing, and oil and gas industries.

There are different types of titanium alloy flanges available, including slip-on, weld neck, blind, and threaded flanges. Slip-on flanges are the most straightforward type and are popular due to their ease of installation. Weld neck flanges are used when high-pressure applications require a robust connection. Blind flanges are used to close off a pipeline temporarily, while threaded flanges allow for easy connection and disconnection of pipes.

Investing in top-quality titanium alloy flanges ensures the longevity and efficiency of your industrial systems. Our range of titanium alloy flanges meets industry standards and specifications, ensuring superior performance and reliability.

"Titanium alloy flanges offer superior performance in harsh environments, making them a popular choice in many industries."

Titanium Forged Flange - Strong and Versatile Solutions

When it comes to demanding industrial environments, titanium forged flanges are the go-to solution. These flanges offer excellent strength and versatility, which make them popular among different industry professionals.

At our company (https://www.intemetal.com), we provide top-quality titanium forged flanges that are perfect for your project needs. Our products are reliable, durable, and cost-effective, which ensures that you get the best value for your investment.

Our experienced manufacturers specialize in producing high-quality titanium forged flanges that meet industry standards and specifications. Whether you need standard sizes or customized options, we have got you covered.

Our titanium forged flanges provide solutions in various industries, including oil and gas, chemical processing, marine engineering, and more. The unique properties of titanium make it an ideal material for challenging environments, where strength, durability, and corrosion resistance are essential.

Advantages of Titanium Forged Flanges

There are several advantages of using titanium forged flanges, including:

- Titanium forged flanges have excellent strength-to-weight ratios, making them lightweight and easy to handle.

- They have high corrosion resistance, making them perfect for use in harsh environmental conditions.

- They are non-magnetic, making them ideal for use in sensitive electronic equipment.

- Titanium is biocompatible, which makes it suitable for use in medical implants.

Overall, titanium forged flanges are strong, durable, and reliable components that provide long-term solutions for various industrial applications. So, if you are looking for top-quality titanium forged flanges, get in touch with us today!

High-Quality Titanium Forging Flanges from Experienced Manufacturers

When it comes to titanium forging flanges, experience and expertise matter. Our team of experienced manufacturers specializes in producing high-quality titanium forging flanges that meet the strictest industry standards and specifications. With our advanced manufacturing techniques and rigorous quality control measures, we ensure superior performance and reliability in all our products.

As a leading titanium flange manufacturer, we understand the importance of delivering products that exceed customer expectations. That's why we work closely with our clients to understand their specific needs and requirements, and offer customized solutions that meet their exact specifications.

Benefits of Choosing our Titanium Forging Flanges

There are many benefits to choosing our titanium forging flanges for your industrial applications. Some of the key advantages include:

- Durability: Our titanium forging flanges are highly durable and resistant to corrosion, making them ideal for use in harsh environments. They are also able to withstand extreme temperatures and pressures without losing their structural integrity.

- Strength: Titanium is one of the strongest metals available, and our forging process further enhances its strength and toughness. This makes our titanium forging flanges ideal for use in demanding applications that require high strength and durability.

- Lightweight: Titanium is a lightweight metal, which makes our forging flanges easy to handle and install. They are also ideal for use in applications where weight reduction is a priority.

- Cost-Effective: While titanium is a premium metal, our forging process allows us to create products that are cost-effective without compromising on quality. This makes our titanium forging flanges a smart investment for your industrial applications.

Applications of Our Titanium Forging Flanges

Our high-quality titanium forging flanges find applications across various industries, including aerospace, marine, chemical processing, and more. Some of the specific applications of our titanium forging flanges include:

| Industry | Application |

|---|---|

| Aerospace | Jet engines, airframes, landing gear |

| Marine | Hull fittings, propeller shafts, valves |

| Chemical Processing | Pumps, compressors, reactors |

| Oil and Gas | Drilling rigs, wellheads, pipelines |

No matter what your industrial application, our titanium forging flanges provide a reliable and durable solution that meets your specific needs.ality construction and durability. The background should be clean and minimalist, with perhaps a subtle gradient or texture that adds depth to the image.

Choose us as your trusted titanium flange manufacturer and experience the benefits of our high-quality, reliable products. Contact us today to learn more.

Premium Titanium Alloy Forgings - Meeting Industry Standards

Our premium titanium alloy forgings are designed to meet and exceed industry standards and specifications, including the ASTM B381 standard.

Made from high-quality titanium alloys, these forgings offer superior strength, durability, and performance in demanding industrial applications.

Our skilled manufacturers use advanced techniques to produce forgings that meet the precise requirements of each project, ensuring consistent quality and reliability.

Advantages of Titanium Alloy Forgings

Titanium alloy forgings offer several advantages over traditional materials, making them a preferred choice for many industries. These advantages include:

- High strength-to-weight ratio

- Excellent corrosion resistance

- High temperature resistance

- Low thermal expansion

- Biocompatibility

These properties make titanium alloy forgings ideal for a wide range of industries, including aerospace, medical, chemical processing, and marine applications.

Applications of ASTM B381 Titanium Forgings

Our premium titanium alloy forgings find applications in various industries, including:

- Aerospace: Engine components, landing gear, and structural parts

- Medical: Implants, surgical instruments, and dental equipment

- Chemical Processing: Heat exchangers, reactors, and tanks

- Marine: Ship components, offshore oil and gas platforms, and desalination plants

These diverse applications showcase the versatility and reliability of titanium alloy forgings in a range of settings.

"Our premium titanium alloy forgings are a testament to our commitment to quality and excellence. With our expertise and state-of-the-art facilities, we can produce forgings that meet and exceed industry standards, ensuring superior performance and reliability."

Order Your Premium Titanium Alloy Forgings Today

If you're in need of premium titanium alloy forgings that meet ASTM B381 standards, look no further than our experienced manufacturers. Contact us today to discuss your project requirements and request a quote.

Wide Range of ANSI B16.5 Titanium Flanges for Every Project

Our inventory includes a wide range of ANSI B16.5 titanium flanges designed to meet diverse project requirements. The ANSI B16.5 standard specifies the dimensions, materials, and marking requirements for pipe flanges and flanged fittings. Using these flanges ensures compatibility and interchangeability with other ANSI B16.5-compliant equipment.

We offer various sizes, pressure classes, facing types, and materials for ANSI B16.5 titanium flanges to suit different industrial applications. The dimensions of these flanges range from 1/2" to 24", with pressure ratings of 150 to 2500. The facing types available are RF (Raised Face), FF (Flat Face), and RTJ (Ring Type Joint). We also provide customized options for special requirements.

| Size (inches) | Pressure Class (lb) | Facing Type |

|---|---|---|

| 1/2" - 24" | 150 - 2500 | RF, FF, RTJ |

Benefits of Using ANSI B16.5 Titanium Flanges

The use of ANSI B16.5 titanium flanges has several benefits, including:

- Compatibility with other ANSI B16.5-compliant equipment, preventing leaks and malfunctions.

- Easy installation and maintenance due to standardized dimensions and materials.

- High strength and durability, ensuring long-term performance in demanding environments.

- Resistance to corrosion, erosion, and high temperatures, protecting against damage and downtime.

- Customizable options, ensuring tailored solutions for unique project needs.

Find the Perfect ANSI B16.5 Titanium Flange for Your Application

Our experienced team can help you choose the right ANSI B16.5 titanium flange for your project requirements. Whether you need a standard size or a custom option, we can provide reliable and efficient solutions for your application. Contact us today to learn more about our products and services.

Reliable Titanium Flange Supplier - Your Trusted Partner

Are you looking for a reliable supplier of titanium flanges? Look no further than our experienced team. As a trusted titanium flange supplier, we prioritize quality, customer satisfaction, and on-time delivery.

We understand that finding affordable, high-quality titanium flanges can be challenging. That's why we focus on providing reliable products and exceptional customer service to meet your needs. We offer a wide range of titanium flanges, including titanium alloy flanges and titanium forged flanges, to meet diverse industrial requirements.

Why Choose Us as Your Titanium Flange Supplier?

- We have years of experience and expertise in producing high-quality titanium flanges for various industries.

- We offer a wide range of products, including customized options, to meet your specific project needs.

- We adhere to strict quality control standards to ensure our products are reliable and durable.

- We prioritize customer satisfaction and on-time delivery to ensure a stress-free experience.

- We offer competitive pricing without compromising on quality.

- We provide excellent customer service, from technical support to after-sales care.

At our company, we understand that the success of your project depends on the quality of the materials you use. That's why we are committed to providing top-quality titanium flanges that meet industry standards and exceed your expectations.

When you choose us as your titanium flange supplier, you can rest assured that you are getting the best products, the best service, and the best value for your money.

"We have been using titanium flanges from this supplier for several years, and we are extremely satisfied with their products and service. Their team is knowledgeable, responsive, and always willing to go the extra mile to meet our needs."

Key Considerations When Choosing Titanium Alloy Flanges and Forgings

Choosing the right titanium alloy flanges and forgings ensures your project runs smoothly. Here are some key considerations:

- Material Selection: Titanium alloys have different properties, so select the alloy that meets your project requirements.

- Specifications: Ensure the flanges and forgings meet relevant standards, such as ASTM B381 for titanium forgings.

- Customization: Determine if customization options, such as surface finishes or unique dimensions, are necessary.

- Supplier: Choose a reliable supplier with experience in producing top-quality titanium alloy flanges and forgings.

- Cost: Consider the cost-benefit ratio of selecting titanium flanges and forgings over other materials.

By keeping these factors in mind, you can select the perfect titanium alloy flanges and forgings for your project needs.

"Choosing the right material is key to success in any project. Selecting the perfect titanium alloy flanges and forgings will ensure maximum performance and durability."

Installation and Maintenance Tips for Titanium Flanges

To ensure optimal performance and longevity of your titanium alloy flanges and titanium forged flange systems, it's essential to follow proper installation and maintenance procedures. Here are some tips to keep in mind:

Installation Tips

- Ensure that the mating surfaces of the flanges are clean and free from any debris, dirt, or other contaminants.

- Use appropriate gaskets made of compatible materials to ensure a tight seal between the flanges.

- Verify that the flange faces are flat and parallel to each other before installation.

- Use proper torque wrenches to tighten the bolts or studs according to manufacturer specifications.

Maintenance Tips

- Regularly inspect the flanges for signs of corrosion, damage, or wear and tear.

- Use appropriate cleaning agents to remove any dirt, debris, or contaminants on the flange surface.

- Store the flanges in a dry, cool, and clean environment to prevent corrosion and degradation.

- Inspect the gaskets periodically and replace them if they show any signs of damage or wear.

By following these tips, you can ensure that your titanium alloy flanges and titanium forged flange systems perform optimally and last for a long time. If you have any questions or concerns regarding the installation and maintenance of titanium flanges, consult with a professional or contact us today.

Applications of Titanium Alloy Flanges and Forgings Across Industries

Titanium alloy flanges and forgings are widely used across many industries due to their unique properties and benefits. Let's explore some of the most common applications of titanium flanges:

Aerospace Industry

The aerospace industry relies heavily on titanium alloy flanges for their high strength-to-weight ratio and corrosion resistance. Titanium flanges are used in the construction of aircraft engines, wing structures, landing gear, and other critical components.

Marine Industry

Titanium flanges are highly resistant to seawater corrosion, making them ideal for use in marine environments. They are used in the construction of boats, ships, and offshore oil rigs, where durability and reliability are essential.

Chemical Industry

The chemical industry requires materials that can withstand extreme temperatures and harsh chemicals. Titanium alloy flanges and forgings offer excellent resistance to corrosion and high-temperature environments, making them ideal for use in chemical processing plants.

Medical Industry

Titanium is biocompatible, meaning it is compatible with living tissue and can be safely used in medical implants and devices. Titanium alloy flanges are used in orthopedic implants, dental implants, and other medical devices due to their strength, durability, and biocompatibility.

Oil and Gas Industry

The oil and gas industry requires materials that can withstand extreme temperatures, pressures, and corrosive environments. Titanium alloy flanges and forgings offer excellent resistance to these conditions and are used in drilling equipment, pipelines, and other critical components.

As you can see, titanium alloy flanges and forgings play a critical role in a wide range of industries. Their unique properties and benefits make them a popular choice for demanding applications where reliability and durability are essential.

At our website, we offer a wide range of customization options for titanium alloy flanges and forgings. With our expertise in manufacturing and customization, we can help you create the perfect solution for your specific project needs.

Our customization options include:

| Option | Description |

|---|---|

| Titanium grade | Choose from a range of titanium grades to meet your required strength, corrosion resistance, and temperature resistance. |

| Size and dimension | Our flanges and forgings can be customized according to your specific size and dimension requirements. |

| Surface finish | Select from a range of surface finishes, including polished, sandblasted, or coated, to suit your application requirements. |

| Shape and design | We can create flanges and forgings in a range of shapes and designs to meet your specific application needs. |

By offering a range of customization options, we can help you find the perfect fit for your project, ensuring optimal performance and longevity. Contact us today to learn more about our customization services.

Conclusion

We hope this article has provided valuable insights into the world of titanium alloy flanges and forgings. Our top-quality products offer reliable and durable solutions for various industrial applications, and with our customization options, we can tailor our offerings to meet your specific needs.

As your trusted partner in titanium flange supply, we prioritize quality, customer satisfaction, and on-time delivery. Our experienced manufacturers specialize in producing high-quality products that meet industry standards and specifications, ensuring superior performance and reliability.

Whether you require ANSI B16.5 titanium flanges or customized titanium alloy forgings, we have you covered. And once you have your products, we are committed to supporting you in maximizing their longevity and efficiency through proper installation and maintenance.

Thank you for considering us for your titanium flange needs. Visit our website today to explore our range of products and find the perfect fit for your projects.

FAQ

What are titanium alloy flanges and titanium forged flanges?

Titanium alloy flanges and titanium forged flanges are components used in various industrial applications. They are made from titanium alloys or forged titanium, offering reliability and durability.

What are the benefits of using titanium alloy flanges?

Titanium alloy flanges provide several benefits, including high strength, corrosion resistance, and lightweight properties. They are also known for their excellent performance in high-temperature and corrosive environments.

Why are titanium forged flanges popular?

Titanium forged flanges are popular due to their strength and versatility. They can withstand extreme conditions and offer excellent fatigue resistance, making them suitable for demanding industrial environments.

Why should I choose high-quality titanium forging flanges?

High-quality titanium forging flanges ensure superior performance and reliability. They are manufactured by experienced manufacturers who have expertise in producing top-quality products for various industrial applications.

What are titanium alloy forgings?

Titanium alloy forgings are components made from titanium alloys using a forging process. They meet industry standards and specifications, including ASTM B381, and are used in various industries for their exceptional properties.

What are ANSI B16.5 titanium flanges?

ANSI B16.5 titanium flanges are flanges that conform to the American National Standards Institute (ANSI) B16.5 standard. They are designed to meet specific dimensions, pressure ratings, and materials for use in piping systems.

Why should I choose you as a titanium flange supplier?

We are a reliable titanium flange supplier known for our commitment to quality, customer satisfaction, and on-time delivery. We prioritize excellence in our products and services, making us a trusted partner for many industries.

What should I consider when choosing titanium alloy flanges and forgings?

When choosing titanium alloy flanges and forgings, consider factors such as material selection, specifications, customization options, and industry standards. It is important to ensure that the components meet your project requirements.

How should I install and maintain titanium flanges?

Proper installation and maintenance of titanium flanges are crucial for their long-term performance. Follow recommended installation procedures and regularly inspect and clean the flanges to ensure their efficiency and longevity.

In which industries are titanium alloy flanges and forgings used?

Titanium alloy flanges and forgings are used across various industries, including aerospace, automotive, chemical processing, oil and gas, marine, and power generation. Their unique properties make them suitable for challenging applications.

Can titanium alloy flanges and forgings be customized?

Yes, titanium alloy flanges and forgings can be customized to meet your specific project requirements. Customization options include sizes, dimensions, surface finishes, and other design specifications to ensure a perfect fit for your application.

2023年12月1日星期五

Industrial valves( check valves, globe valves, butterfly valves, ball valves, control valves) descriptions

Industrial valves descriptions

Check valves:

Globe valves: A globe valve is a type of valve used to control the flow of a liquid or gas in a pipeline. It consists of a movable disk-shaped element and a stationary ring seat, usually in the shape of a globe. When the valve is fully open, the disk is lifted completely out of the flow path, allowing for maximum flow. Conversely, when the valve is closed, the disk is pressed against the seat, blocking the flow entirely.

2023年11月30日星期四

Explore the differences between gate valves and globe valves

Differences between gate valves and globe valves

Gate valves and globe valves are both common types of valves used to control the flow of fluids in pipes.

However, there are some key differences between the two types of valves.

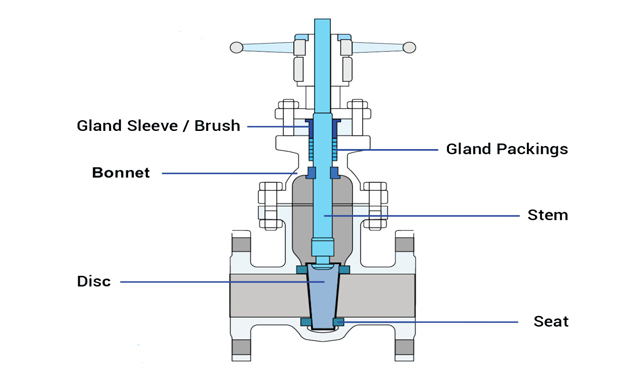

Gate valves

• Gate valves use a gate-like disc to close off the flow of fluid.

• Gate valves are typically used for on/off applications.

• Gate valves are not as good at throttling flow as globe valves.

• Gate valves are typically larger and heavier than globe valves.

Globe Valves

• Globe valves use a plug or ball to close off the flow of fluid.

• Globe valves can be used for on/off applications and for throttling flow.

• Globe valves are more compact than gate valves.

• Globe valves are typically more expensive than gate valves.

Here is a table summarizing the key differences between gate valves and globe valves:

Feature | Gate Valve | Globe Valve |

Closure mechanism | Gate-like disc | Plug or ball |

Applications | On/off | On/off and throttling |

Flow control | Not as good | Good |

Size and weight | Larger and heavier | Smaller and lighter |

Cost | Less expensive | More expensive |

In general, gate valves are a good choice for applications where on/off control is needed and where throttling is not a major concern. Globe valves are a good choice for applications where both on/off control and throttling are needed.

Here are some additional factors to consider when choosing between a gate valve and a globe valve:

• The type of fluid: Gate valves are generally better suited for handling viscous fluids, while globe valves are better suited for handling non-viscous fluids.

• The pressure rating: The pressure rating of the valve must be high enough to withstand the maximum pressure in the system.

• The size of the valve: The size of the valve must be large enough to accommodate the flow rate of the fluid.

• The type of connection: The type of connection must be compatible with the piping system.

• The cost: The cost of the valve must be factored into your budget.

Explore the Properties and Performance Characteristics of Molybdenum Rods

Explore the Properties and Performance Characteristics of Molybdenum Rods

Introduction

Molybdenum rods are essential components in various industries, including aerospace, electronics, chemicals, and more. Due to its high strength, durability, and resistance to heat and corrosion, molybdenum is a highly sought-after material. However, finding reliable suppliers of high-quality molybdenum rods can be challenging.

Molybdenum rods are a type of metal rod that is made from molybdenum, a silvery-gray, metallic transition metal with a high melting point (2,617 °C) and a low coefficient of thermal expansion. Molybdenum rods are used in a variety of applications, including aerospace, electronics, chemicals, and industrial. They are known for their high strength, hardness, and resistance to heat, corrosion, and wear.

Properties of Molybdenum Rods

High strength: Molybdenum rods have a tensile strength of 250 MPa, which is higher than the tensile strength of most other metals. This makes them ideal for applications where high strength is required, such as in aircraft engines and turbines.

High hardness: Molybdenum rods have a Brinell hardness number (BHN) of 550, which is very hard. This makes them resistant to scratching, abrasion, and wear and tear.

High melting point: Molybdenum rods have a melting point of 2,617 °C, which is one of the highest melting points of any metal. This makes them ideal for applications where high temperatures are required, such as in furnaces and reactors.

Low coefficient of thermal expansion: Molybdenum rods have a low coefficient of thermal expansion, which means that they do not expand or contract very much when they are heated or cooled. This makes them ideal for applications where dimensional stability is required, such as in precision instruments and tools.

Resistance to heat, corrosion, and wear: Molybdenum rods are resistant to heat, corrosion, and wear and tear. This makes them ideal for applications where these factors are present, such as in chemical processing plants and power plants

Performance Characteristics of Molybdenum Rods

High strength-to-weight ratio: Molybdenum rods have a high strength-to-weight ratio, which means that they are very strong for their weight. This makes them ideal for applications where weight is a concern, such as in aerospace applications.

Good electrical conductivity: Molybdenum rods have a good electrical conductivity, which means that they can conduct electricity well. This makes them ideal for applications where electrical conductivity is required, such as in electrical circuits and components.

Good thermal conductivity: Molybdenum rods have a good thermal conductivity, which means that they can conduct heat well. This makes them ideal for applications where heat transfer is required, such as in heat sinks and heat exchangers.

Good machinability: Molybdenum rods can be machined to a high degree of accuracy, which makes them ideal for applications where precision is required.

Biocompatible: Molybdenum rods are biocompatible, which means that they are not toxic or harmful to living tissue. This makes them ideal for applications where biocompatibility is required, such as in medical implants

_%E5%89%AF%E6%9C%AC.png)

Why Choose HC Moly?

Seeking High-Performance Molybdenum Rods?

Look no further than our exceptional molybdenum rods, meticulously crafted to meet the stringent requirements of ASTM B387 standards. Our rods boast exceptional purity levels of 99.95%, ensuring unmatched performance and reliability in diverse applications.

HC Moly is a leading supplier and manufacturer of molybdenum rods in China. We offer a wide range of molybdenum rods to meet the diverse needs of our customers. Our rods are known for their exceptional quality and competitive pricing. Here are the Whys:

Unparalleled Precision and Polish

Each rod undergoes rigorous dimensional checks, guaranteeing adherence to your precise specifications. Additionally, their polished surfaces enhance their aesthetic appeal and functionality.

Assuring Quality with Mill Test Reports

For your peace of mind, we provide comprehensive mill test reports accompanying each rod, meticulously documenting their chemical composition, mechanical properties, and adherence to industry standards.

Diverse Applications, Limitless Possibilities

Our molybdenum rods cater to a wide spectrum of industries, including aerospace, electronics, chemicals, and manufacturing. Their exceptional properties make them ideal for high-temperature applications, demanding strength requirements, and corrosion-resistant environments.

Prompt Delivery and Expert Assistance

We maintain a well-stocked inventory, ensuring prompt delivery of your molybdenum rods. Our experienced team is always available to assist you with your specific requirements, providing expert guidance and technical support.

Contact us today to experience the pinnacle of molybdenum rod excellence.

Molybdenum rods properties

High purity molybdenum possesses unique properties that are suitable for use in a number of applications and industries. For example, its high melting point, 2620 °C, drives its performance in high-temperature environments. HC Moly starts with the highest quality Mo powder to ensure our final product always meets our customer’s application needs. In addition, we will modify the manufacturing processes to meet even the most exacting application requirements that our customers have.

Category: Transition Metal, Group VI

Atomic Number: 42

Density: 10.28 g / cm3

Discovered: 1778

High melting temperature, 2620 °C

Low vapor pressure at high temperature

Low coefficient of thermal expansion (CTE)

Good thermal and electrical conductivity

High density

Good corrosion and creep resistance

Load bearing capabilities at temperatures up to 2000 °C,

Molybdenum Rods Product Specifications

Our molybdenum rods are made from 99.95% pure molybdenum and are available in diameters ranging from 10mm to 100mm and lengths from 100mm to 1500mm. We can also customize the rods to meet your specific requirements.

Molybdenum rods | |||

Purity | 99.95% min | Density | 10.2g/cm3 |

Surface | Polished or Oxidized surface | Process | Hot-rolling |

Melting point | 2610℃ | Boiling point | 4615℃ |

Molybdenum Rods Dimensions and Tolerances

Diameter (mm) | Diameter Tolerance(mm) | Length (mm) | Tolerance(mm) |

16-20 | +1.0 | 300-1500 | +2 |

20-30 | +1.5 | 250-1500 | +2 |

30-45 | +1.5 | 200-1500 | +3 |

45-60 | +2.0 | 250-1300 | +3 |

60-100 | +2.5 | 250-800 | +3 |

Applications

Molybdenum rods are used in a wide variety of applications, including:

1. Aerospace: Molybdenum rods are used in aircraft engines, turbines, and other high-temperature components.

2. Electronics: Molybdenum rods are used in semiconductors, capacitors, and other electronic devices.

3. Chemicals: Molybdenum rods are used in catalysts and other chemical processing equipment.

4. Industrial: Molybdenum rods are used in cutting tools, dies, and other industrial applications.

ASTM B387 Molybdenum Rods

We offer a wide range of ASTM B387 molybdenum rods, including:

1. Grade A: This grade is suitable for general applications.

2. Grade B: This grade is suitable for applications where higher strength and hardness are required.

3. Grade C: This grade is suitable for applications where the highest strength and hardness are required.

How to Order

To order HC Moly molybdenum rods, please contact us today. We will be happy to discuss your specific requirements and provide you with a quote.

Conclusion

HC Moly is a reliable supplier of high-quality molybdenum rods at competitive prices. We are committed to providing our customers with the best possible products and services.

Explore the application of check valves in power plants

Explore the application of check valves in power plants

Check valves basic information

This particular check valve is available in sizes ranging from DN50 to DN300, referring to the nominal diameter of the valve. It has a pressure rating ranging from PN1.6 to 335 MPa (megapascal), indicating the maximum pressure it can withstand.

The valve body and components of the check valve can be made from different materials based on the specific requirements. Carbon steel, stainless steel, or steel alloy are commonly used materials for high-temperature and high-pressure applications due to their strength and resistance to corrosion and heat.

These check valves are commonly used in industries such as oil and gas, petrochemical, power generation, and refining. They are suitable for applications where reliable prevention of backflow or reverse flow is critical, such as in high-pressure steam systems or high-temperature fluid processes.

The high-temperature and high-pressure check valves provide a reliable sealing mechanism and are designed to withstand extreme operating conditions. Proper selection of materials ensures compatibility with the fluid media and environmental conditions.

Butterfly Valves: A Comprehensive Guide

Butterfly Valves: A Comprehensive Guide

Butterfly valves are a type of quarter-turn valve that uses a disc to control the flow of fluids. They are commonly used in various industries including oil and gas, water treatment, HVAC, and power generation.

Here is some information about butterfly valves:

The Importance of check valves in Power Plants

The Importance of check valves in Power Plants Check valves are commonly used in various industrial applications, including power plants, to...

-

The Importance of check valves in Power Plants Check valves are commonly used in various industrial applications, including power plants, to...

-

ASTM B363 TITANIUM PIPE FITTINGS Prev Next We are a titanium pipe fittings suplier in China, we produce titanium pipe fittings in vari...

-

Industrial valves descriptions Check valves: Globe valves: A globe valve is a type of valve used to control the flow of a liquid or gas in ...